C11000 Copper Pipe

C11000 Electrolytic Tough Pitch (ETP) Copper is known for its high electrical and thermal conductivity, good corrosion resistance and solderability. C11000 copper is used for welding fixtures, anodes, bus bar in electrical power installations, ground straps, commutators and current-carrying hardware. Its inherent fabrication qualities readily permit it to be bent, soldered, drilled, peened, riveted and formed to fit almost any design specification. This copper has excellent hot workability.

Standard: GB, ASTM, CDA, BS, DIN, JIS

Length: 3m, 5.8m, 6m, 11.8m,12m, or as required

Price Term: FOB, CIF, CFR, etc

Package: Wooden pallet/Woven bag with bundle in points

Delivery Time: 7-15 days, According to order's quantity

Application: Building Fronts, Gutters, Skylight Frames, Roofing, Flashing, Downspouts, Spouting

Pressure Vessels, Chemical Process Equipment, Chlorine Cells, Chimney Cap Screens, Heat Exchangers, Printing Rolls, Anodes, Rotating Bands, Kettles, Pans, Vats, Road Bed Expansion Plates

C11000 Electrolytic Tough Pitch (ETP) Copper is produced by the direct conversion of selected refined cathodes and castings under carefully controlled conditions to prevent contamination of the pure oxygen-free metal during processing. The method of producing OFHC copper ensures extra high grade of metal with a copper content of 99.99%. With so small a content of extraneous elements, the inherent properties of elemental copper are brought forth to a high degree.

Product Name | C11000 Copper Pipe/Tube |

Material | C1220,C12000,C10200,T1,T2,T3,TP2,TU1,TU2,TU3,H62, H65,H70,etc |

Standard | GB/T17791-2007,GB/T1527-2006, GB/T18033-2007, YS/T450-2002 ASTM B280,ASTM B68,ASTM B75,ASTM B88 EN12735,AS1571,JIS H3300,etc. |

Model Number | 3/16'',1/4 ",3/8",1/2", 5/8" ,3/4" 7/ 8'' ,1'' copper tube |

OD | 3/16'',1/4 ",3/8",1/2", 5/8" ,3/4" 7/ 8'' ,1'' or Customized |

Ultimate Strength | 370MPa |

Elongation (≥ %) | 40% |

Length | 15m/roll, 50m/roll or customized |

Hardness | 1/16 hard,1/8 hard,3/8 hard,1/4 hard,1/2hard,full hard. |

Temper | O-H112; T3-T8; T351-T851 |

Surface | Mill finish, polished, anodizing, brushing, sand blasting, powder coating,etc |

Application | Building Fronts, Gutters, Skylight Frames, Roofing, Flashing, Downspouts, Spouting Pressure Vessels, Chemical Process Equipment, Chlorine Cells, Chimney Cap Screens, Heat Exchangers, Printing Rolls, Anodes, Rotating Bands, Kettles, Pans, Vats, Road Bed Expansion Plates. |

Samples | Can provide samples |

Certification | ISO9001,CE.ect. |

MOQ | 200 kg, If the purchase quantity is less than our MOQ, can be customized according to your requirements. |

Payment | T/T, D/A, D/P, L/C, Western Union, Money Gram or according to customer requirements. |

Delivery time | Usually within 7 days, the time depends on the number of products. |

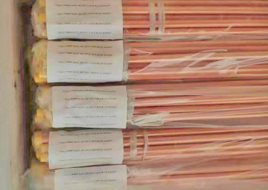

Package | 1. Pancake coil copper tube:individually sealed by plastic bag,and packed by carton or box of 3-20 rolls 2. LWC(plain) copper tube:withunit weight 100kgs more and packed individually by reel,6-7 coils packed by one pallet 3. Straight copper tube:Each piece end capped,bundled with plastic bag,then put in the wooden box or container 4. The packaging can be customized according to customer requirements. |

Advantages | 1. Reasonable price with excellent quality 2. Abundant stock and prompt delivery 3. Rich supply and export experience, sincere service |

Product Inventory

We are a professional copper dealer. With the support of the most professional copper manufacturers and a large number of customers, we can not only provide you with ordinary copper but also help you find very personalized copper, such as special copper grades, Special sizes, special craft shapes,etc.

Packaging And Shipping

We adopt standard export shipping packaging according to the size of the copper pipe. According to our delivery experience, a 20-foot container can hold 22 tons of copper, and a 40-foot container can hold 25 tons of copper. For larger orders, we use bulk vessels to transport you, and the price is cheaper. Also, we can customize the packaging according to the needs of customers.

Our Service

We offer a wide range of advanced and standard copper machining services for customers. We specialize in customized machining services to meet your most challenging copper needs.

The copper services we can provide include turning, milling, planing, drilling, boring, grinding, gear cutting and CNC machining services. Of course, we can offer deformation processing services such as bending, cutting, rolling, and stamping.

Why choose us ?

We provide our customers with unbeatable service, while providing top quality products at competitive prices. By treating people the way we want to be treated our customers have come to trust Steel Sales and the work we do.We work alongside our customers, big and small,to make sure their unique needs are met. Our experience helps us contribute to each customer's success.

Submitted successfully

We will contact you as soon as possible