Aluminum extrusion is a versatile, heat-dependent process used to shape aluminum alloys into unique cross-sectional profiles.

Contact Now

Aluminum extrusion is a versatile, heat-dependent process used to shape aluminum alloys into unique cross-sectional profiles.

Contact Now

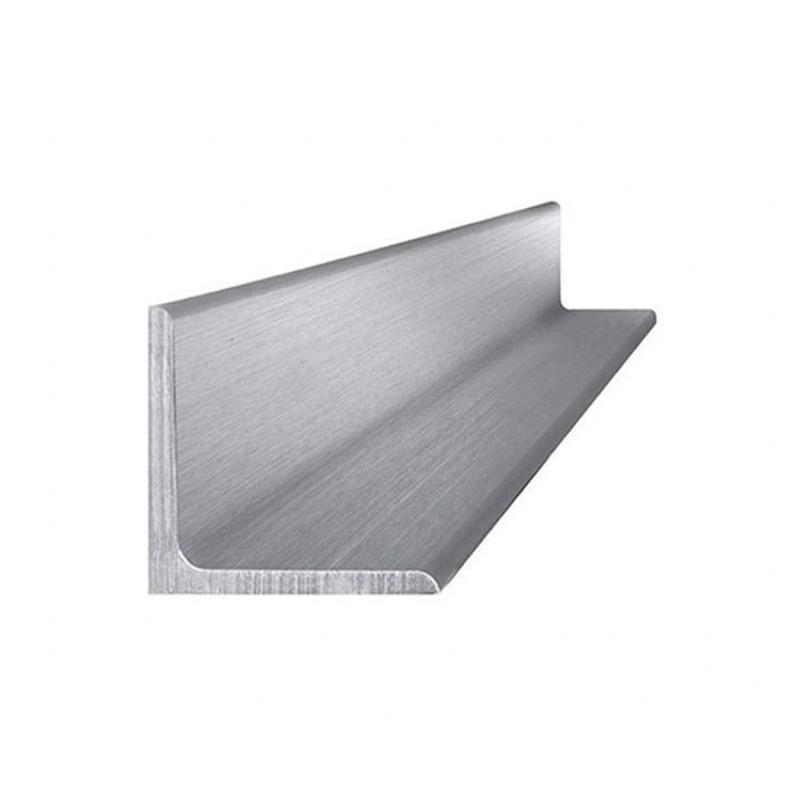

Stainless steel angle stock has two pieces that come together to form a 90° angle. These angles are strong, durable, and available in different material grades for general use as well as applications in highly corrosive environments.Feathurs1. Stainless steel has different grades, correspond to different hardness, thermoplastic, plasticity and weldability. If you don't understand, you can tell us your requirements. 2. Stainless steel can be customized for different surfaces, and different surfaces have different applications.

Contact Now

Stainless steel H-beam Introduction It is an economical section and high-efficiency profile with a more optimized cross-sectional area distribution.And because its legs inside and outside parallel, leg end is a right Angle, assembled into components, can save the workload of welding and riveting up to 25%.

Contact Now

Stainless steel H-beam Introduction It is an economical section and high-efficiency profile with a more optimized cross-sectional area distribution.And because its legs inside and outside parallel, leg end is a right Angle, assembled into components, can save the workload of welding and riveting up to 25%.

Contact Now

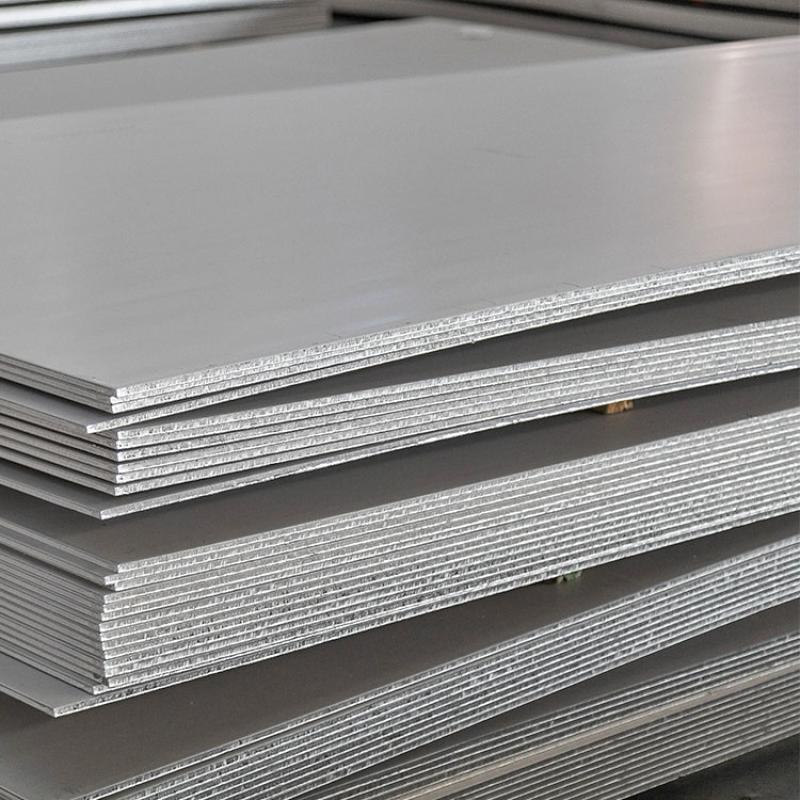

Stainless steel flat steel can be used to form various stress components according to different structural needs, and can also be used as a connector between components. It is widely used in various building structures and engineering structures, such as house beams, bridges, transmission towers, hoisting and transportation machinery, ships, industrial furnaces, reaction towers, container racks and warehouse shelves.Stainless steel flat steel is used for bridges, frames, fences, power transmission ships, vehicles, etc. in construction projects.

Contact Now

Stainless steel flat steel can be used to form various stress components according to different structural needs, and can also be used as a connector between components. It is widely used in various building structures and engineering structures, such as house beams, bridges, transmission towers, hoisting and transportation machinery, ships, industrial furnaces, reaction towers, container racks and warehouse shelves.Stainless steel flat steel is used for bridges, frames, fences, power transmission ships, vehicles, etc. in construction projects.

Contact Now

Stainless steel flat steel can be used to form various stress components according to different structural needs, and can also be used as a connector between components. It is widely used in various building structures and engineering structures, such as house beams, bridges, transmission towers, hoisting and transportation machinery, ships, industrial furnaces, reaction towers, container racks and warehouse shelves.Stainless steel flat steel is used for bridges, frames, fences, power transmission ships, vehicles, etc. in construction projects.

Contact Now

Stainless steel flat steel can be used to form various stress components according to different structural needs, and can also be used as a connector between components. It is widely used in various building structures and engineering structures, such as house beams, bridges, transmission towers, hoisting and transportation machinery, ships, industrial furnaces, reaction towers, container racks and warehouse shelves.Stainless steel flat steel is used for bridges, frames, fences, power transmission ships, vehicles, etc. in construction projects.

Contact Now

Stainless steel angle steel can form various stress components according to different structural needs, and can also be used as a connector between components. It is widely used in various building structures and engineering structures, such as house beams, bridges, transmission towers, hoisting and transportation machinery, ships, industrial furnaces, reaction towers, container racks and warehouse shelves.Feathurs1. Stainless steel has different grades, correspond to different hardness, thermoplastic, plasticity and weldability.

Contact Now

Grade 904L is a non-stabilised low carbon high alloy austenitic stainless steel. The addition of copper to this grade gives it greatly improved resistance to strong reducing acids,particularly sulphuric acid.

Contact Now

439 stainless steel angle is perpendicular to both sides with a specified Angle of formed steel. It has excellent strength, corrosion resistance and weldability, indicated as width by width by edge thickness (mm).

Contact Now

2205 is a ferritic-austenitic stainless steel which combines many of the beneficial properties of both ferritic and austenitic steels. As a result of high chromium and molybdenum contents, the steel has very good pitting and uniform corrosion resistance to stress corrosion cracking as well as high mechanical strength. 2205 has good weldability and can be welded using most of the welding techniques for stainless steels. Due to the balanced composition, when welded correctly, the heat affected zone contains sufficient austenite to avoid the risk of localized corrosion.Feathurs1.

Contact Now

201 stainless steel angle is perpendicular to both sides with a specified Angle of formed steel. It has excellent strength, corrosion resistance and weldability, indicated as width by width by edge thickness (mm).

Contact Now

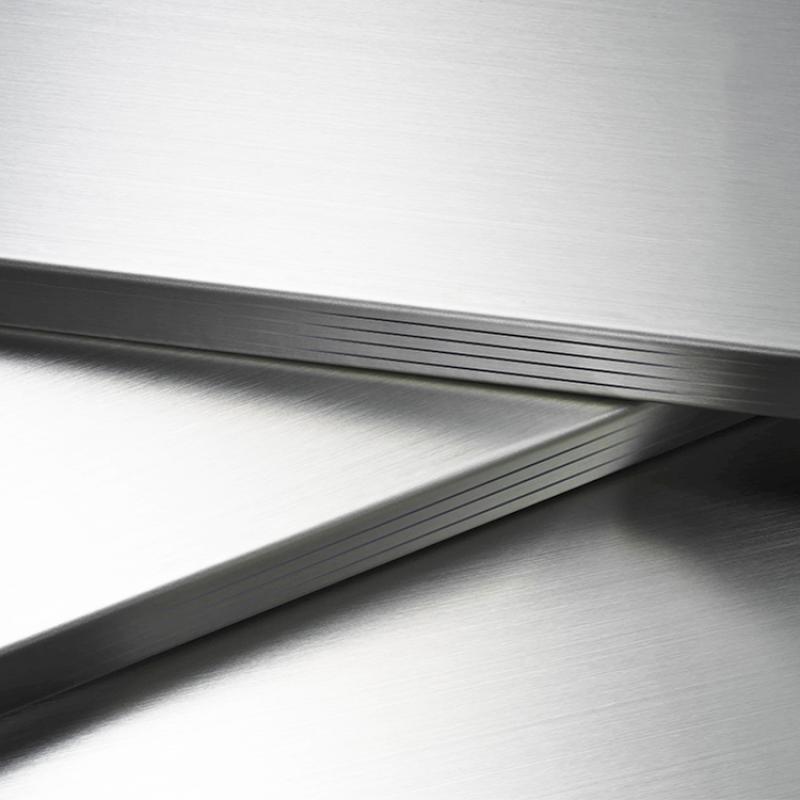

Stainless steel is referred to as stainless steel, it is composed of stainless steel and acid steel two parts, can resist atmospheric corrosion steel called stainless steel, and can resist the corrosion of chemical medium steel called acid steel.

Contact Now

Stainless steel is one of the world’s most commonly used and trusted materials. It’s versatile, durable, and corrosion-resistant, which makes it an excellent choice for many applications. Among the various types of stainless steel available, 304L plates are the most popular.Feathurs1. Stainless steel has different grades, correspond to different hardness, thermoplastic, plasticity and weldability. If you don't understand, you can tell us your requirements. 2. Stainless steel can be customized for different surfaces, and different surfaces have different applications.

Contact Now

304L Stainless steel angle can form various stress components according to different structural needs, and can also be used as a connector between components. It is widely used in various building structures and engineering structures, such as house beams, bridges, transmission towers, hoisting and transportation machinery, ships, industrial furnaces, reaction towers, container racks and warehouse shelves.Feathurs1. Stainless steel has different grades, correspond to different hardness, thermoplastic, plasticity and weldability.

Contact Now

316L Stainless steel angle can form various stress components according to different structural needs, and can also be used as a connector between components. It is widely used in various building structures and engineering structures, such as house beams, bridges, transmission towers, hoisting and transportation machinery, ships, industrial furnaces, reaction towers, container racks and warehouse shelves.Feathurs1. Stainless steel has different grades, correspond to different hardness, thermoplastic, plasticity and weldability.

Contact Now

Stainless steel H-beam Introduction It is an economical section and high-efficiency profile with a more optimized cross-sectional area distribution.And because its legs inside and outside parallel, leg end is a right Angle, assembled into components, can save the workload of welding and riveting up to 25%.

Contact Now

316L is actually a stainless steel material, which contains a certain amount of Mo element. The performance of this steel has exceeded that of 301 steel and 304 stainless steel. It has a very wide range of applications. Even in high-temperature environment, it will not be eroded and corroded by high temperature. It can also be used in the marine environment, and will not be polluted by some outer air, resulting in corrosion.Feathurs1. Stainless steel has different grades, correspond to different hardness, thermoplastic, plasticity and weldability.

Contact Now

Stainless steel is a kind of material with brightness close to mirror surface, tough and cold touch. It is a relatively avant-garde decorative material with excellent corrosion resistance, formability, compatibility and toughness. It is used in heavy industry and light industry, Daily necessities industry and architectural decoration industries.Feathurs1. Stainless steel has different grades, correspond to different hardness, thermoplastic, plasticity and weldability. If you don't understand, you can tell us your requirements. 2.

Contact Now

Stainless steel unequal angles two pieces that come together to form a 90° angle. These angles are strong, durable, and available in different material grades for general use as well as applications in highly corrosive environments.Feathurs1. Stainless steel has different grades, correspond to different hardness, thermoplastic, plasticity and weldability. If you don't understand, you can tell us your requirements. 2. Stainless steel can be customized for different surfaces, and different surfaces have different applications.

Contact Now

Stainless Steel 301 is a commonly available austenitic stainless steel with good corrosion resistance and elevated carbon to allow for cold working to a variety of tempers. Grade 301 stainless steel is highly ductile, for formed products.

Contact Now

Due to the molybdenum content of 316 stainless steel, this stainless-steel material delivers superior corrosion and heat resistance. It withstands a variety of corrodents such as sulfuric acid, bromides, iodides, and chlorides and can, therefore, be used in marine environments.Stainless steel flat steel is used for bridges, frames, fences, power transmission ships, vehicles, etc. in construction projects.

Contact Now