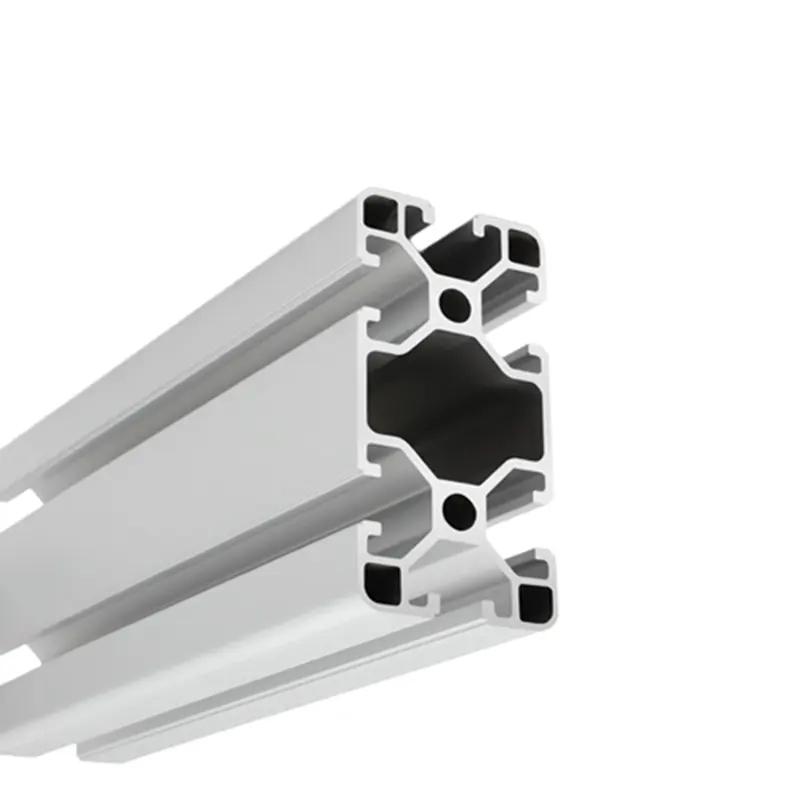

Aluminum extrusion is a versatile, heat-dependent process used to shape aluminum alloys into unique cross-sectional profiles.

Contact Now

Aluminum profile, it is different section shapes aluminum products through aluminum extrusion process. From raw material-aluminum ingot, after hot melting, get aluminum billets, and then finish aluminum extrusion process through porthole die or flat die, can get different shape aluminum products. Aluminum ProfileStandardJIS, AiSi, ASTM, GB, DIN, EN etcGrade1000 Series,2000,3000 Series,4000Series,5000Series,6000Series,7000Series,8000Series,,9000Series Size1-6m or According to RequestSurfaceCoated, Embossed,Brushed, polished, Anodized,etcOEM service Per

Contact Now

Aluminum Alloy 6063, one of the most popular alloys in the 6000 series, provides good extrudability and high quality surface finish. In heat-treated condition, alloy 6063 provides good resistance to general corrosion, including resistance to stress corrosion cracking. It is easily welded or brazed by various commercial methods. Alloy 6063 main uses and applications are: Architectural and building applications, Extrusions, Window frames, Doors, Shop fittings, Pipes and tubes for Irrigation systems, Railing and furniture's.

Contact Now

Aluminum profile, it is different section shapes aluminum products through aluminum extrusion process.

Contact Now

Aluminum ingots are a type of metal with many uses in today’s industries. It is most often used for manufacturing parts and components, as well as for producing aluminum products.Aluminum ingots have many uses across different industries. One of the most common applications is in the manufacturing industry, where they can be used to create parts and components for cars, computers, electronics, machinery, etc. They can also be used in the construction industry to make window frames, doors, siding, roofing materials, etc.

Contact Now

Stainless steel H-beam Introduction It is an economical section and high-efficiency profile with a more optimized cross-sectional area distribution.And because its legs inside and outside parallel, leg end is a right Angle, assembled into components, can save the workload of welding and riveting up to 25%.

Contact Now

Stainless steel H-beam Introduction It is an economical section and high-efficiency profile with a more optimized cross-sectional area distribution.And because its legs inside and outside parallel, leg end is a right Angle, assembled into components, can save the workload of welding and riveting up to 25%.

Contact Now

Stainless steel H-beam Introduction It is an economical section and high-efficiency profile with a more optimized cross-sectional area distribution.And because its legs inside and outside parallel, leg end is a right Angle, assembled into components, can save the workload of welding and riveting up to 25%.

Contact Now

Stainless steel H-beam Introduction It is an economical section and high-efficiency profile with a more optimized cross-sectional area distribution.And because its legs inside and outside parallel, leg end is a right Angle, assembled into components, can save the workload of welding and riveting up to 25%.

Contact Now

Stainless steel H-beam Introduction It is an economical section and high-efficiency profile with a more optimized cross-sectional area distribution.And because its legs inside and outside parallel, leg end is a right Angle, assembled into components, can save the workload of welding and riveting up to 25%.

Contact Now

Stainless steel H-beam Introduction It is an economical section and high-efficiency profile with a more optimized cross-sectional area distribution.And because its legs inside and outside parallel, leg end is a right Angle, assembled into components, can save the workload of welding and riveting up to 25%.

Contact Now

5083 Aluminum Pipe is one of many aluminum alloys used in different industries. It has fine granular structure that allows it to be easily and precisely anodized. The addition of magnesium and other elements in this alloy makes it much corrosion resistant under marine environments.

Contact Now

Stainless steel H-beam Introduction It is an economical section and high-efficiency profile with a more optimized cross-sectional area distribution.And because its legs inside and outside parallel, leg end is a right Angle, assembled into components, can save the workload of welding and riveting up to 25%.

Contact Now

The aluminum profiles and compatible accessories make it easy to build handrails, signage, flow racks and more. Build to your own technical specification. We go the extra mile as a full service custom industrial solutions provider.

Contact Now

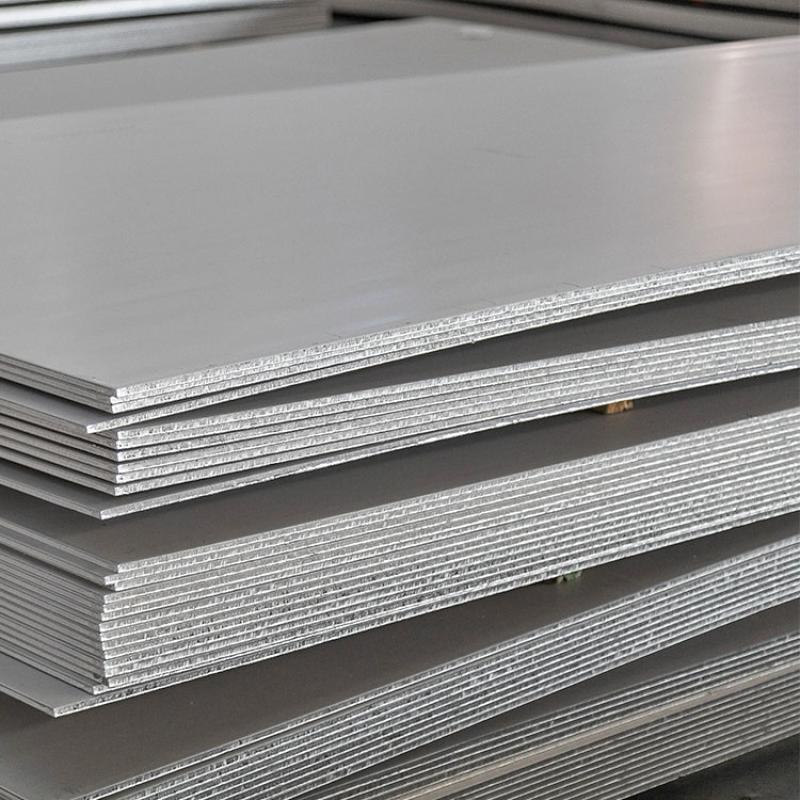

Aluminum 5052 has moderate-to-high strength characteristics with good weldability and resistance to corrosion. Due to its light weight, high strength, and attractive finishing capabilities, it can be used to make smaller, thinner components, such as those used in consumer electronics.

Contact Now

Aluminum ingots is non-ferrous product that is produced by pouring molten aluminum into special molds. These molds come in a variety of sizes and shapes, and the ingots created by this variety have different types in appearance.

Contact Now

Aluminum ingots is non-ferrous product that is produced by pouring molten aluminum into special molds. These molds come in a variety of sizes and shapes, and the ingots created by this variety have different types in appearance.

Contact Now

Aluminum extrusion is a versatile, heat-dependent process used to shape aluminum alloys into unique cross-sectional profiles.

Contact Now

Aluminum ingots is non-ferrous product that is produced by pouring molten aluminum into special molds. These molds come in a variety of sizes and shapes, and the ingots created by this variety have different types in appearance.

Contact Now

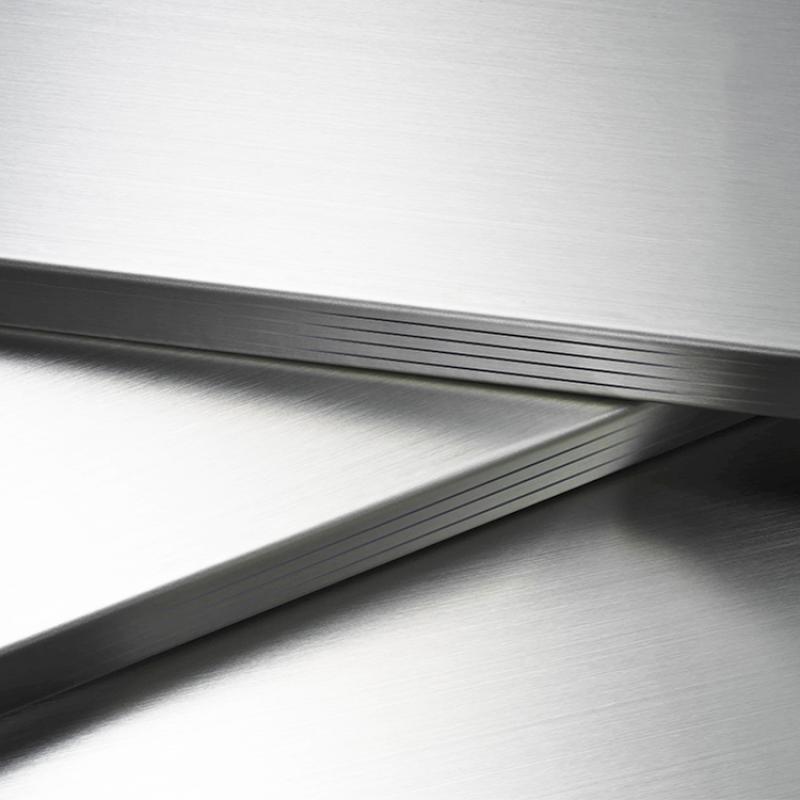

While 2024 aluminum was initially designed for structural components in aircraft, it's now widely used when a high strength-to-weight ratio is needed, such as for gears, shafts, and fasteners.

Contact Now

6061 Aluminum Pipe is an extruded aluminum product that is very versatile and has a wide range of applications. 6061 Aluminum pipe is made from one of the most widely used heat treatable aluminum alloys.

Contact Now

Aluminum extrusion is a versatile, heat-dependent process used to shape aluminum alloys into unique cross-sectional profiles.

Contact Now

5086 aluminum is used on ships, oil rigs, tanks, and pressure vessels because of its excellent saltwater resistance and formability.Choose from our selection of aluminum 5086 pipe in a wide range of styles and sizes.

Contact Now