Aluminum ingots is non-ferrous product that is produced by pouring molten aluminum into special molds. These molds come in a variety of sizes and shapes, and the ingots created by this variety have different types in appearance.

Contact Now

Aluminium foil is a thin sheet of metal foil comprising about 92-99% aluminum. Its thickness is typically between 0.0002 to 0.006 inches. Its width and intensity are very different due to expected applications.

Contact Now

Aluminium foil is a thin sheet of metal foil comprising about 92-99% aluminum. Its thickness is typically between 0.0002 to 0.006 inches. Its width and intensity are very different due to expected applications.

Contact Now

Aluminium foil is a thin sheet of metal foil comprising about 92-99% aluminum. Its thickness is typically between 0.0002 to 0.006 inches. Its width and intensity are very different due to expected applications.

Contact Now

Aluminum ingots is non-ferrous product that is produced by pouring molten aluminum into special molds. These molds come in a variety of sizes and shapes, and the ingots created by this variety have different types in appearance.

Contact Now

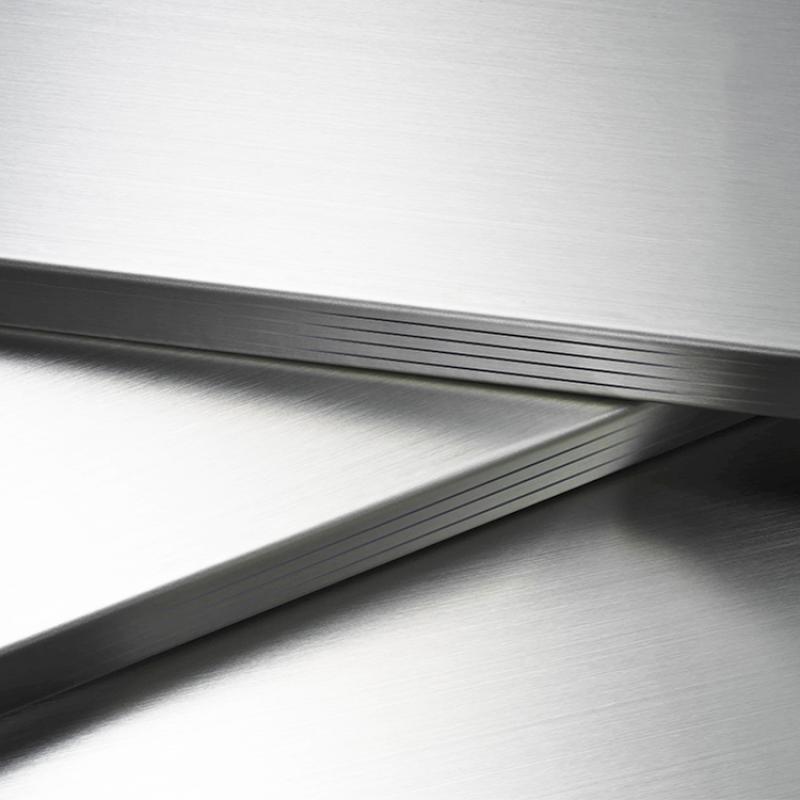

Aluminum Plate refers to the rectangular plate processed by aluminum ingot rolling, which is divided into pure aluminum plate, alloy aluminum plate, thin aluminum plate, medium thickness aluminum plate, pattern aluminum plate.

Contact Now

Stainless Steel Sheet is versatile and used in a variety of applications. It is primarily selected for its resistance to corrosion, longevity and formability. Typical uses of Stainless Steel Sheet include, construction, food service applications, transportation, chemical, marine, and textile industries.Stainless steel producers take advantage of the properties of stainless steel to improve quality through various surface treatments.

Contact Now

Tinplate consists of sheets of steel coated with a thin layer of tin to impede rusting. Before the advent of cheap milled steel, the backing metal was wrought iron.

Contact Now

Aluminium foil is a thin sheet of metal foil comprising about 92-99% aluminum. Its thickness is typically between 0.0002 to 0.006 inches. Its width and intensity are very different due to expected applications.

Contact Now

Aluminium foil is a thin sheet of metal foil comprising about 92-99% aluminum. Its thickness is typically between 0.0002 to 0.006 inches. Its width and intensity are very different due to expected applications.

Contact Now

Tinplate consists of sheets of steel coated with a thin layer of tin to impede rusting. Before the advent of cheap milled steel, the backing metal was wrought iron.

Contact Now

Alloy 6061 coils and sheets are the most versatile of the heat treatable aluminum alloys. Though less strong than most of the 2xxx and 7xxx alloys, 6061 aluminum provides an extensive range of mechanical properties and corrosion resistance and can be fabricated by many of the commonly used practices. In the "O" temper or annealed condition, alloy 6061 has good formability.

Contact Now

Aluminum ingots are a type of metal with many uses in today’s industries. It is most often used for manufacturing parts and components, as well as for producing aluminum products.Aluminum ingots have many uses across different industries. One of the most common applications is in the manufacturing industry, where they can be used to create parts and components for cars, computers, electronics, machinery, etc. They can also be used in the construction industry to make window frames, doors, siding, roofing materials, etc.

Contact Now

Tinplate consists of sheets of steel coated with a thin layer of tin to impede rusting. Before the advent of cheap milled steel, the backing metal was wrought iron.

Contact Now

The 1050 aluminum alloy is formed with a small amount of copper in pure aluminium, which has remarkable forming characteristics, high corrosion resistance, good weldability and conductivity.

Contact Now

While 2024 aluminum was initially designed for structural components in aircraft, it's now widely used when a high strength-to-weight ratio is needed, such as for gears, shafts, and fasteners.

Contact Now

3003 aluminum coil and sheet is approximately 20% stronger than 1100 series aluminum. 3003 aluminum reacts well to mechanical finishings as well as organic finishes. 3003 welding is readily accomplished by means of conventional welding methods, but may be gummy if machined.

Contact Now

Aluminum Alloy 6063, one of the most popular alloys in the 6000 series, provides good extrudability and high quality surface finish. In heat-treated condition, alloy 6063 provides good resistance to general corrosion, including resistance to stress corrosion cracking. It is easily welded or brazed by various commercial methods. Alloy 6063 main uses and applications are: Architectural and building applications, Extrusions, Window frames, Doors, Shop fittings, Pipes and tubes for Irrigation systems, Railing and furniture's.

Contact Now

Aluminum ingots is non-ferrous product that is produced by pouring molten aluminum into special molds. These molds come in a variety of sizes and shapes, and the ingots created by this variety have different types in appearance.

Contact Now

Aluminum extrusion is a versatile, heat-dependent process used to shape aluminum alloys into unique cross-sectional profiles.

Contact Now

The aluminium copper alloy 2024 is competitive on a strength-to-weight ratio with the higher-strength but heavier titanium and steel alloys and thus has traditionally been the dominant structural material in both commercial and military aircraft. In addition, aluminium alloys are not embrittled at low temperatures and become even stronger as the temperature is decreased, without significant ductility losses, making them ideal for cryogenic fuel tanks for rockets and launch vehicles.

Contact Now

Aluminium alloy 6063 is a medium strength alloy commonly referred to as an architectural alloy. It is normally used in intricate extrusions. It has a good surface finish, high corrosion resistance, is readily suited to welding and can be easily anodized.

Contact Now

6061 Aluminum Pipe is an extruded aluminum product that is very versatile and has a wide range of applications. 6061 Aluminum pipe is made from one of the most widely used heat treatable aluminum alloys.

Contact Now

Aluminum extrusion is a versatile, heat-dependent process used to shape aluminum alloys into unique cross-sectional profiles.

Contact Now