Aluminum ingots is non-ferrous product that is produced by pouring molten aluminum into special molds. These molds come in a variety of sizes and shapes, and the ingots created by this variety have different types in appearance.

Contact Now

Aluminum ingots is non-ferrous product that is produced by pouring molten aluminum into special molds. These molds come in a variety of sizes and shapes, and the ingots created by this variety have different types in appearance.

Contact Now

Aluminum ingots is non-ferrous product that is produced by pouring molten aluminum into special molds. These molds come in a variety of sizes and shapes, and the ingots created by this variety have different types in appearance.

Contact Now

Aluminum ingot is product in the form of a bar with an above narrowing. It is produced using molding in a horizontal position through an open top.Ingots of pure aluminum or aluminum alloy after special processing are used in the production of pipes, sheets, hexagon drives and other rolled products.

Contact Now

Aluminum ingots is non-ferrous product that is produced by pouring molten aluminum into special molds. These molds come in a variety of sizes and shapes, and the ingots created by this variety have different types in appearance.

Contact Now

Aluminum ingots is non-ferrous product that is produced by pouring molten aluminum into special molds. These molds come in a variety of sizes and shapes, and the ingots created by this variety have different types in appearance.

Contact Now

Aluminum ingot is product in the form of a bar with an above narrowing. It is produced using molding in a horizontal position through an open top.Ingots of pure aluminum or aluminum alloy after special processing are used in the production of pipes, sheets, hexagon drives and other rolled products.

Contact Now

Aluminum ingot is product in the form of a bar with an above narrowing. It is produced using molding in a horizontal position through an open top.Ingots of pure aluminum or aluminum alloy after special processing are used in the production of pipes, sheets, hexagon drives and other rolled products.

Contact Now

Aluminum ingots is non-ferrous product that is produced by pouring molten aluminum into special molds. These molds come in a variety of sizes and shapes, and the ingots created by this variety have different types in appearance.

Contact Now

Aluminum ingot is product in the form of a bar with an above narrowing. It is produced using molding in a horizontal position through an open top.Ingots of pure aluminum or aluminum alloy after special processing are used in the production of pipes, sheets, hexagon drives and other rolled products.

Contact Now

Aluminum ingots is non-ferrous product that is produced by pouring molten aluminum into special molds. These molds come in a variety of sizes and shapes, and the ingots created by this variety have different types in appearance.

Contact Now

Aluminum ingots is non-ferrous product that is produced by pouring molten aluminum into special molds. These molds come in a variety of sizes and shapes, and the ingots created by this variety have different types in appearance.

Contact Now

Aluminum ingots is non-ferrous product that is produced by pouring molten aluminum into special molds. These molds come in a variety of sizes and shapes, and the ingots created by this variety have different types in appearance.

Contact Now

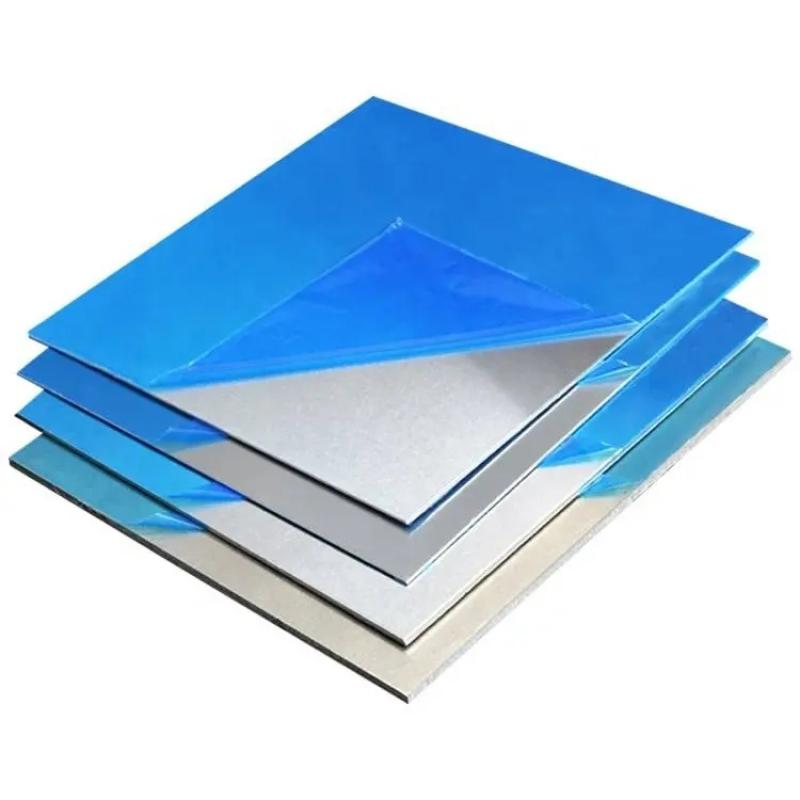

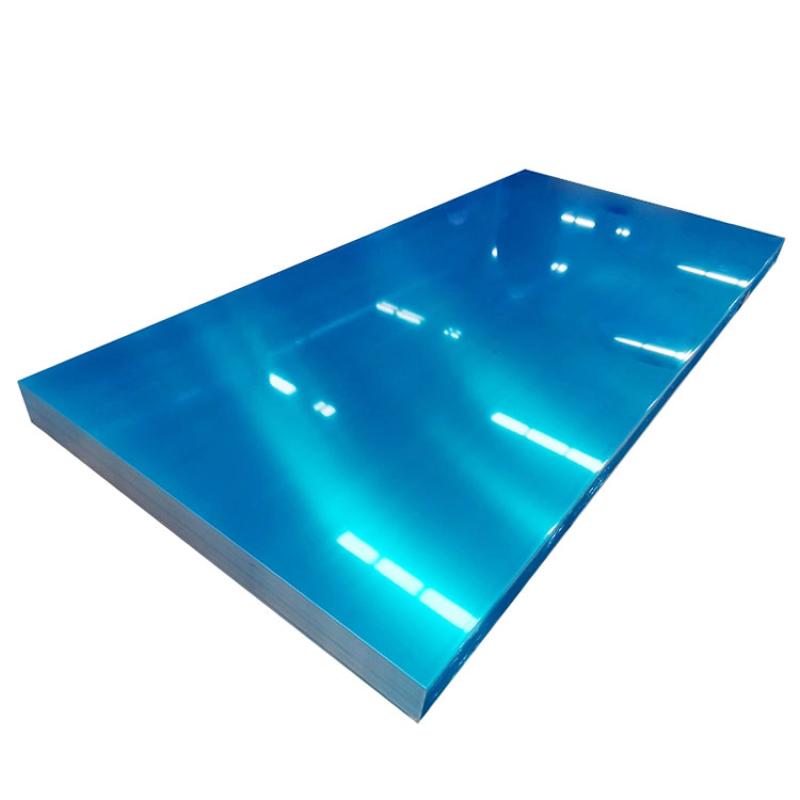

Aluminum Plate refers to the rectangular plate processed by aluminum ingot rolling, which is divided into pure aluminum plate, alloy aluminum plate, thin aluminum plate, medium thickness aluminum plate, pattern aluminum plate.

Contact Now

Aluminum ingots is non-ferrous product that is produced by pouring molten aluminum into special molds. These molds come in a variety of sizes and shapes, and the ingots created by this variety have different types in appearance.

Contact Now

Aluminum Plate refers to the rectangular plate processed by aluminum ingot rolling, which is divided into pure aluminum plate, alloy aluminum plate, thin aluminum plate, medium thickness aluminum plate, pattern aluminum plate.

Contact Now

Aluminum Plate refers to the rectangular plate processed by aluminum ingot rolling, which is divided into pure aluminum plate, alloy aluminum plate, thin aluminum plate, medium thickness aluminum plate, pattern aluminum plate.

Contact Now

Aluminum Plate refers to the rectangular plate processed by aluminum ingot rolling, which is divided into pure aluminum plate, alloy aluminum plate, thin aluminum plate, medium thickness aluminum plate, pattern aluminum plate.

Contact Now

Aluminum Plate refers to the rectangular plate processed by aluminum ingot rolling, which is divided into pure aluminum plate, alloy aluminum plate, thin aluminum plate, medium thickness aluminum plate, pattern aluminum plate.

Contact Now

Aluminum Plate refers to the rectangular plate processed by aluminum ingot rolling, which is divided into pure aluminum plate, alloy aluminum plate, thin aluminum plate, medium thickness aluminum plate, pattern aluminum plate.

Contact Now

Aluminum Plate refers to the rectangular plate processed by aluminum ingot rolling, which is divided into pure aluminum plate, alloy aluminum plate, thin aluminum plate, medium thickness aluminum plate, pattern aluminum plate.

Contact Now

Aluminum Plate refers to the rectangular plate processed by aluminum ingot rolling, which is divided into pure aluminum plate, alloy aluminum plate, thin aluminum plate, medium thickness aluminum plate, pattern aluminum plate.

Contact Now

Aluminum Plate refers to the rectangular plate processed by aluminum ingot rolling, which is divided into pure aluminum plate, alloy aluminum plate, thin aluminum plate, medium thickness aluminum plate, pattern aluminum plate.

Contact Now

Aluminum Plate refers to the rectangular plate processed by aluminum ingot rolling, which is divided into pure aluminum plate, alloy aluminum plate, thin aluminum plate, medium thickness aluminum plate, pattern aluminum plate.

Contact Now