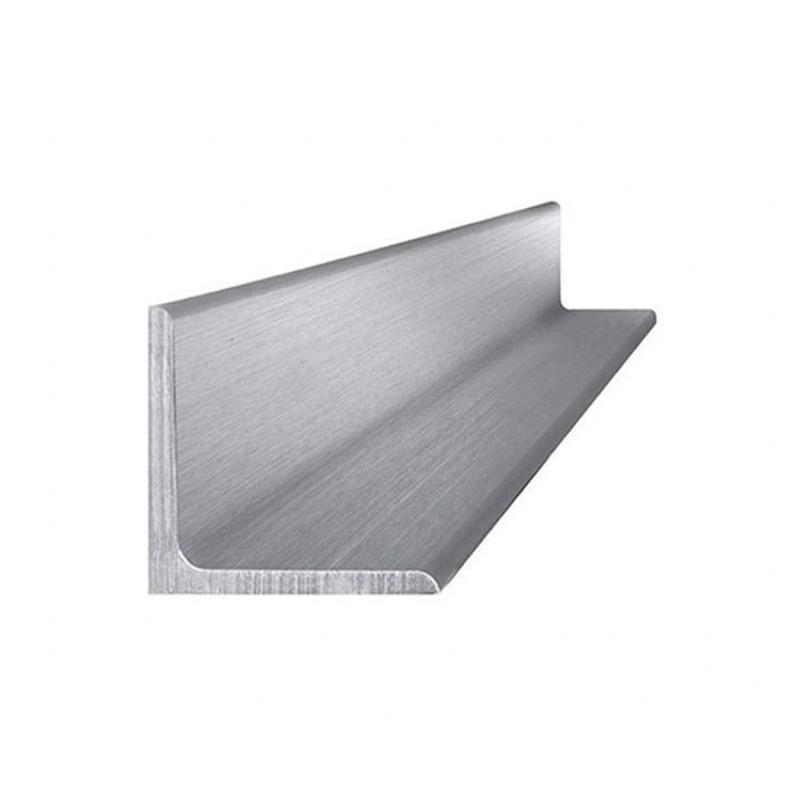

316L Stainless steel angle can form various stress components according to different structural needs, and can also be used as a connector between components. It is widely used in various building structures and engineering structures, such as house beams, bridges, transmission towers, hoisting and transportation machinery, ships, industrial furnaces, reaction towers, container racks and warehouse shelves.Feathurs1. Stainless steel has different grades, correspond to different hardness, thermoplastic, plasticity and weldability.

Contact Now

439 stainless steel angle is perpendicular to both sides with a specified Angle of formed steel. It has excellent strength, corrosion resistance and weldability, indicated as width by width by edge thickness (mm).

Contact Now

201 stainless steel angle is perpendicular to both sides with a specified Angle of formed steel. It has excellent strength, corrosion resistance and weldability, indicated as width by width by edge thickness (mm).

Contact Now

Stainless steel angle steel can form various stress components according to different structural needs, and can also be used as a connector between components. It is widely used in various building structures and engineering structures, such as house beams, bridges, transmission towers, hoisting and transportation machinery, ships, industrial furnaces, reaction towers, container racks and warehouse shelves.Feathurs1. Stainless steel has different grades, correspond to different hardness, thermoplastic, plasticity and weldability.

Contact Now

Stainless Steel Equal Legs Angle Bar is offered in both equal and unequal leg lengths. This product is ideal for structural applications that require strength and durability as the inside radius corner reinforces the shape. The steel angle also offers exceptional corrosion resistance for environments that are acidic, chemical-heavy, and even freshwater or saltwater saturated.Feathurs1. Stainless steel has different grades, correspond to different hardness, thermoplastic, plasticity and weldability. If you don't understand, you can tell us your requirements. 2.

Contact Now

Stainless steel angle stock has two pieces that come together to form a 90° angle. These angles are strong, durable, and available in different material grades for general use as well as applications in highly corrosive environments.Feathurs1. Stainless steel has different grades, correspond to different hardness, thermoplastic, plasticity and weldability. If you don't understand, you can tell us your requirements. 2. Stainless steel can be customized for different surfaces, and different surfaces have different applications.

Contact Now

316L steel is a molybdenum-containing stainless steel. Due to the molybdenum content in the steel, the overall performance of the 316L stainless steel is better than that of 310 and 304 stainless steel. Under the condition of high temperature, 316L stainless steel has a wide range of usage.Feathurs1. Stainless steel has different grades, correspond to different hardness, thermoplastic, plasticity and weldability. If you don't understand, you can tell us your requirements. 2. Stainless steel can be customized for different surfaces, and different surfaces have different applications.

Contact Now

304L Stainless steel angle can form various stress components according to different structural needs, and can also be used as a connector between components. It is widely used in various building structures and engineering structures, such as house beams, bridges, transmission towers, hoisting and transportation machinery, ships, industrial furnaces, reaction towers, container racks and warehouse shelves.Feathurs1. Stainless steel has different grades, correspond to different hardness, thermoplastic, plasticity and weldability.

Contact Now

Stainless steel H-beam Introduction It is an economical section and high-efficiency profile with a more optimized cross-sectional area distribution.And because its legs inside and outside parallel, leg end is a right Angle, assembled into components, can save the workload of welding and riveting up to 25%.

Contact Now

316L is actually a stainless steel material, which contains a certain amount of Mo element. The performance of this steel has exceeded that of 301 steel and 304 stainless steel. It has a very wide range of applications. Even in high-temperature environment, it will not be eroded and corroded by high temperature. It can also be used in the marine environment, and will not be polluted by some outer air, resulting in corrosion.Feathurs1. Stainless steel has different grades, correspond to different hardness, thermoplastic, plasticity and weldability.

Contact Now

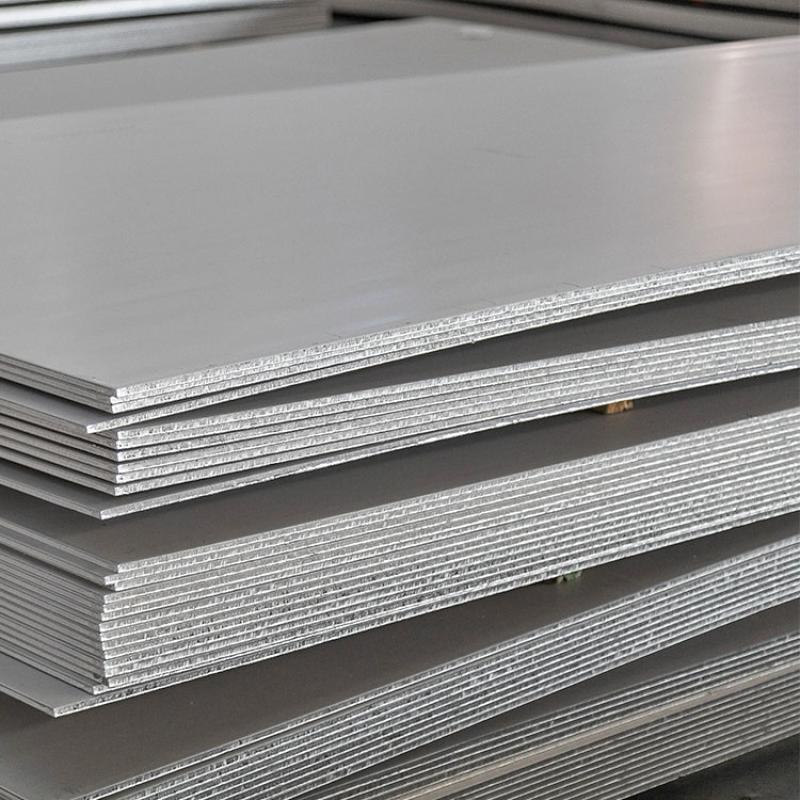

Stainless steel flat steel can be used to form various stress components according to different structural needs, and can also be used as a connector between components. It is widely used in various building structures and engineering structures, such as house beams, bridges, transmission towers, hoisting and transportation machinery, ships, industrial furnaces, reaction towers, container racks and warehouse shelves.Stainless steel flat steel is used for bridges, frames, fences, power transmission ships, vehicles, etc. in construction projects.

Contact Now

316L is actually a stainless steel material, which contains a certain amount of Mo element. The performance of this steel has exceeded that of 301 steel and 304 stainless steel. It has a very wide range of applications. Even in high-temperature environment, it will not be eroded and corroded by high temperature. It can also be used in the marine environment, and will not be polluted by some outer air, resulting in corrosion.Feathurs1. Stainless steel has different grades, correspond to different hardness, thermoplastic, plasticity and weldability.

Contact Now

These 304 stainless steel angles maintain their physical properties at high temperatures. These angles are strong, durable, and often used for parts in food and beverage, chemical processing, and cryogenic industries.Feathurs1. Stainless steel has different grades, correspond to different hardness, thermoplastic, plasticity and weldability. If you don't understand, you can tell us your requirements. 2. Stainless steel can be customized for different surfaces, and different surfaces have different applications. For example, 8k mirrors are generally used for decoration. 3.

Contact Now

These 316 stainless steel angles maintain their physical properties at high temperatures. These angles are strong, durable, and often used for parts in food and beverage, chemical processing, and cryogenic industries.Feathurs1. Stainless steel has different grades, correspond to different hardness, thermoplastic, plasticity and weldability. If you don't understand, you can tell us your requirements. 2. Stainless steel can be customized for different surfaces, and different surfaces have different applications. For example, 8k mirrors are generally used for decoration. 3.

Contact Now

Stainless steel H-beam Introduction It is an economical section and high-efficiency profile with a more optimized cross-sectional area distribution.And because its legs inside and outside parallel, leg end is a right Angle, assembled into components, can save the workload of welding and riveting up to 25%.

Contact Now

Stainless steel H-beam Introduction It is an economical section and high-efficiency profile with a more optimized cross-sectional area distribution.And because its legs inside and outside parallel, leg end is a right Angle, assembled into components, can save the workload of welding and riveting up to 25%.

Contact Now

Stainless steel unequal angles two pieces that come together to form a 90° angle. These angles are strong, durable, and available in different material grades for general use as well as applications in highly corrosive environments.Feathurs1. Stainless steel has different grades, correspond to different hardness, thermoplastic, plasticity and weldability. If you don't understand, you can tell us your requirements. 2. Stainless steel can be customized for different surfaces, and different surfaces have different applications.

Contact Now

Grade 316 is the standard molybdenum-bearing austenitic grade, particularly higher resistance to pitting and crevice corrosion in chloride environments. It is readily brake or roll formed,welded, soldered and cut by both thermal and mechanical methods.The austenitic structure gives excellent toughness, even down to cryogenic temperatures.Grade 316L, the low carbon version of 316, is highly resistant to sensitisation (grain boundary carbide precipitation) and so is extensively used in heavy gauge welded components (about 5mm and over).

Contact Now

Type 321 (UNS S32100) is titanium stabilized Austenitic stainless steel with excellent resistance to intergranular corrosion and high-temperature properties. Alloy 321H (UNS S 32109) is the higher carbon version of the alloy, was used for where enhanced creep resistance required or higher strength at temperatures above 537°C.Feathurs1. Stainless steel has different grades, correspond to different hardness, thermoplastic, plasticity and weldability. If you don't understand, you can tell us your requirements. 2.

Contact Now

The 316L Stainless Steel Seamless Pipe is used in more dimensionally accurate applications. The pipes have lower carbide precipitation while welding and reduce the intergranular corrosion and localized corrosion. The seamless pipes range from ½ inches to 16 inches. The Stainless Steel 316L Welded Pipe ranges from ½ inches to 24 inches and the electric fusion welded pipes range from 6 inches to 100 inches. The tubular products are suitable for high pressure and high temperature services in this grade of material.Feathurs1.

Contact Now

Stainless steel flat steel can be used to form various stress components according to different structural needs, and can also be used as a connector between components. It is widely used in various building structures and engineering structures, such as house beams, bridges, transmission towers, hoisting and transportation machinery, ships, industrial furnaces, reaction towers, container racks and warehouse shelves.Stainless steel flat steel is used for bridges, frames, fences, power transmission ships, vehicles, etc. in construction projects.

Contact Now

Stainless steel flat steel can be used to form various stress components according to different structural needs, and can also be used as a connector between components. It is widely used in various building structures and engineering structures, such as house beams, bridges, transmission towers, hoisting and transportation machinery, ships, industrial furnaces, reaction towers, container racks and warehouse shelves.Stainless steel flat steel is used for bridges, frames, fences, power transmission ships, vehicles, etc. in construction projects.

Contact Now

Stainless steel sheet is an alloy steel with smooth surface, high weldability, corrosion resistance, polishability, heat resistance, corrosion resistance and other characteristics. It is widely used in various industries and is an important material in modern industry. Stainless steel is divided into austenitic stainless steel, ferritic stainless steel, martensitic stainless steel, and duplex stainless steel according to the structure state.Feathurs1. Stainless steel has different grades, correspond to different hardness, thermoplastic, plasticity and weldability.

Contact Now

The 316L Stainless Steel Welded Pipe is used in more dimensionally accurate applications. The pipes have lower carbide precipitation while welding and reduce the intergranular corrosion and localized corrosion. The seamless pipes range from ½ inches to 16 inches. The Stainless Steel 316L Welded Pipe ranges from ½ inches to 24 inches and the electric fusion welded pipes range from 6 inches to 100 inches. The tubular products are suitable for high pressure and high temperature services in this grade of material.Feathurs1.

Contact Now