These 304 stainless steel angles maintain their physical properties at high temperatures. These angles are strong, durable, and often used for parts in food and beverage, chemical processing, and cryogenic industries.Feathurs1. Stainless steel has different grades, correspond to different hardness, thermoplastic, plasticity and weldability. If you don't understand, you can tell us your requirements. 2. Stainless steel can be customized for different surfaces, and different surfaces have different applications. For example, 8k mirrors are generally used for decoration. 3.

Contact Now

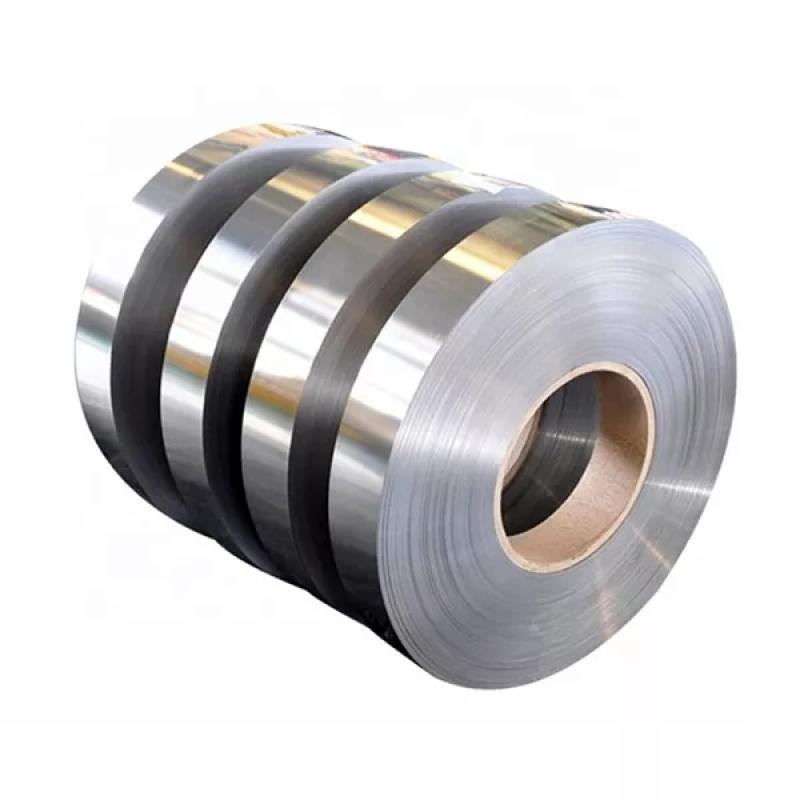

Stainless steel strips have excellent strength, precision surface finish, and are widely used in many industries such as aerospace, petrochemicals, automobiles, textiles, electronics, home appliances, computers, and precision parts processing.Feathurs1. Stainless steel has different grades, correspond to different hardness, thermoplastic, plasticity and weldability. If you don't understand, you can tell us your requirements. 2. Stainless steel can be customized for different surfaces, and different surfaces have different applications.

Contact Now

304 Stainless Steel Seamless Pipes / Tubes are widely used in commercial and industrial fields, especially fluid transportation. With appropriate processes, they have superior performance in high pressure, high strength, and corrosion resistance.Feathurs1. Stainless steel has different grades, correspond to different hardness, thermoplastic, plasticity and weldability. If you don't understand, you can tell us your requirements. 2. Stainless steel can be customized for different surfaces, and different surfaces have different applications.

Contact Now

Stainless steel strips have excellent strength, precision surface finish, and are widely used in many industries such as aerospace, petrochemicals, automobiles, textiles, electronics, home appliances, computers, and precision parts processing.Feathurs1. Stainless steel has different grades, correspond to different hardness, thermoplastic, plasticity and weldability. If you don't understand, you can tell us your requirements. 2. Stainless steel can be customized for different surfaces, and different surfaces have different applications.

Contact Now

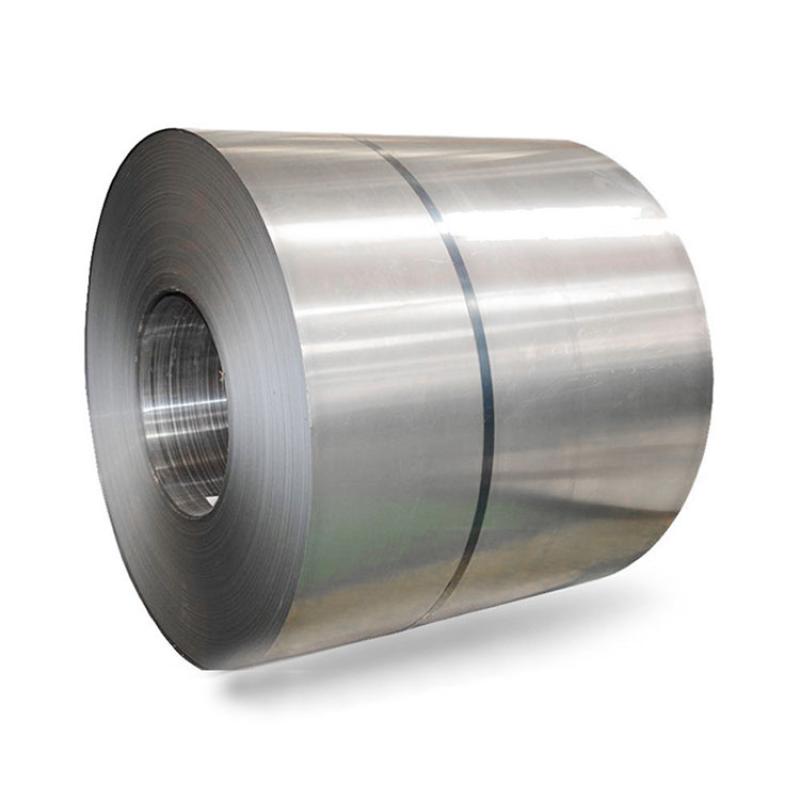

304 stainless steel coil is also used for components that are exposed to high temperatures or aggressive corrosive environments such as condensers, heat exchangers and furnace parts where oxidation resistance is required.Feathurs1. Stainless steel has different grades, correspond to different hardness, thermoplastic, plasticity and weldability. If you don't understand, you can tell us your requirements. 2. Stainless steel can be customized for different surfaces, and different surfaces have different applications. For example, 8k mirrors are generally used for decoration. 3.

Contact Now

Stainless Type 304 is one of the most versatile and commonly used grades of stainless steel. It is a Chromium-Nickel austenitic alloy containing a minimum of 18% Chromium and 8% Nickel with a max of 0.08% Carbon. It cannot be hardened by heat treatment but cold working can produce higher tensile strengths. The Chromium and Nickel alloy provide Type 304 with corrosion and oxidation resistance far superior to steel or iron. It has lower carbon content than 302 which enable it to minimize chromium carbide precipitation due to welding and intergranular corrosion.

Contact Now

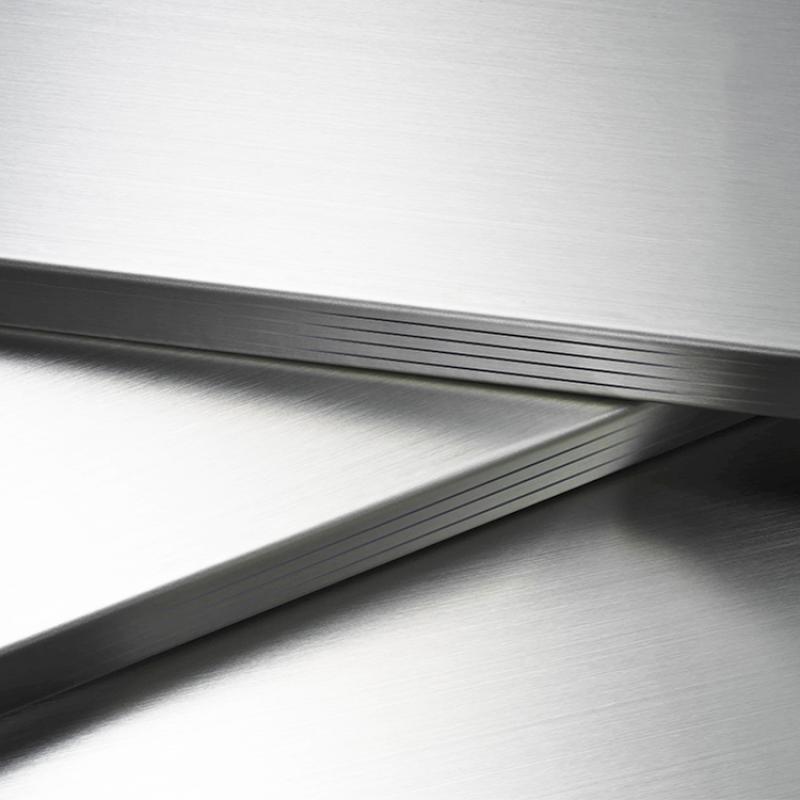

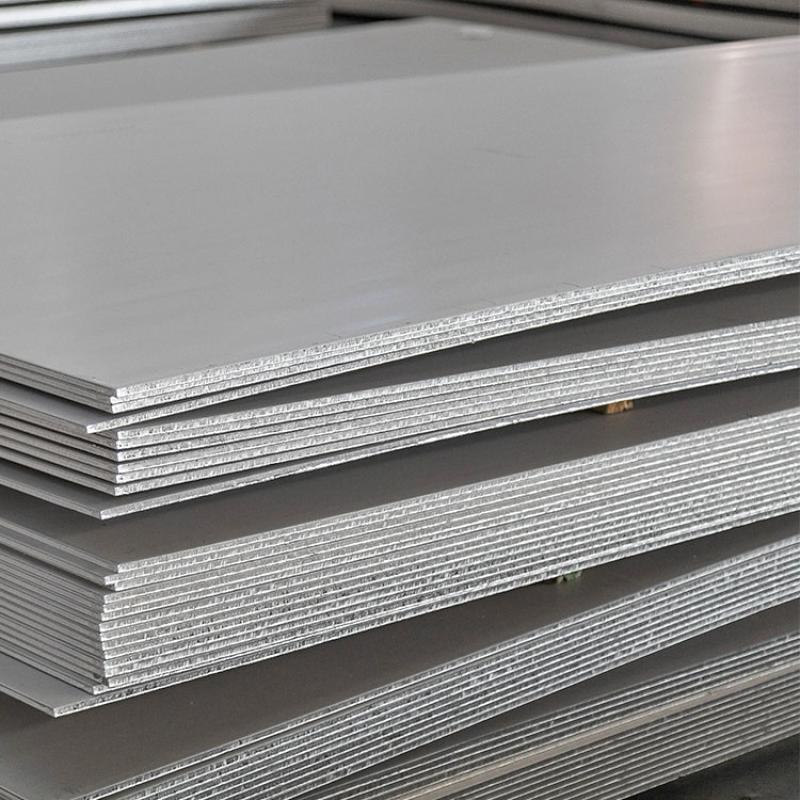

Stainless Steel 304 sheets are a type of austenitic stainless steel commonly used in various industrial and commercial applications also they are made primarily of iron and a combination of chromium, nickel, and other alloying elements. Stainless Steel 304 sheet is a versatile material with excellent corrosion resistance, high strength, and good formability. The 304 grade is one of the most widely used stainless steel due to its many beneficial properties.

Contact Now

304 stainless steel is the most widely used chromium nickel stainless steel. As a widely used steel, it has good corrosion resistance, heat resistance, low temperature strength and mechanical properties; Good hot workability such as stamping and bending, no heat treatment hardening phenomenon (service temperature -196 ℃ ~ 800 ℃). It is corrosion-resistant in the atmosphere. If it is an industrial atmosphere or a heavily polluted area, it needs to be cleaned in time to avoid corrosion. Suitable for food processing, storage and transportation.

Contact Now

304 stainless steel is the most widely used chromium nickel stainless steel. As a widely used steel, it has good corrosion resistance, heat resistance, low temperature strength and mechanical properties; Good hot workability such as stamping and bending, no heat treatment hardening phenomenon (service temperature -196 ℃ ~ 800 ℃). It is corrosion-resistant in the atmosphere. If it is an industrial atmosphere or a heavily polluted area, it needs to be cleaned in time to avoid corrosion. Suitable for food processing, storage and transportation.

Contact Now

316L steel is a molybdenum-containing stainless steel. Due to the molybdenum content in the steel, the overall performance of the 316L stainless steel is better than that of 310 and 304 stainless steel. Under the condition of high temperature, 316L stainless steel has a wide range of usage.Feathurs1. Stainless steel has different grades, correspond to different hardness, thermoplastic, plasticity and weldability. If you don't understand, you can tell us your requirements. 2. Stainless steel can be customized for different surfaces, and different surfaces have different applications.

Contact Now

Stainless steel strips have excellent strength, precision surface finish, and are widely used in many industries such as aerospace, petrochemicals, automobiles, textiles, electronics, home appliances, computers, and precision parts processing.Feathurs1. Stainless steel has different grades, correspond to different hardness, thermoplastic, plasticity and weldability. If you don't understand, you can tell us your requirements. 2. Stainless steel can be customized for different surfaces, and different surfaces have different applications.

Contact Now

304L stainless steel plate is better than 304 in pitting corrosion resistance at welding points or other treatment places.

Contact Now

Stainless steel strips have excellent strength, precision surface finish, and are widely used in many industries such as aerospace, petrochemicals, automobiles, textiles, electronics, home appliances, computers, and precision parts processing.Feathurs1. Stainless steel has different grades, correspond to different hardness, thermoplastic, plasticity and weldability. If you don't understand, you can tell us your requirements. 2. Stainless steel can be customized for different surfaces, and different surfaces have different applications.

Contact Now

316L is actually a stainless steel material, which contains a certain amount of Mo element. The performance of this steel has exceeded that of 301 steel and 304 stainless steel. It has a very wide range of applications. Even in high-temperature environment, it will not be eroded and corroded by high temperature. It can also be used in the marine environment, and will not be polluted by some outer air, resulting in corrosion.Feathurs1. Stainless steel has different grades, correspond to different hardness, thermoplastic, plasticity and weldability.

Contact Now

Stainless steel flat steel can be used to form various stress components according to different structural needs, and can also be used as a connector between components. It is widely used in various building structures and engineering structures, such as house beams, bridges, transmission towers, hoisting and transportation machinery, ships, industrial furnaces, reaction towers, container racks and warehouse shelves.Stainless steel flat steel is used for bridges, frames, fences, power transmission ships, vehicles, etc. in construction projects.

Contact Now

Stainless steel is one of the world’s most commonly used and trusted materials. It’s versatile, durable, and corrosion-resistant, which makes it an excellent choice for many applications. Among the various types of stainless steel available, 304L plates are the most popular.Feathurs1. Stainless steel has different grades, correspond to different hardness, thermoplastic, plasticity and weldability. If you don't understand, you can tell us your requirements. 2. Stainless steel can be customized for different surfaces, and different surfaces have different applications.

Contact Now

Stainless Steel Coils are one of the most sought after types of raw material in the construction and manufacturing industries. Thanks to their distinct mechanical and physical properties, stainless steel coils have been widely used in the production of kitchen appliances to industrial equipment. They are strong, resist corrosion, are light in weight and require low maintenance. Stainless steel producers take advantage of the properties of stainless steel to improve quality through various surface treatments. We provide different types of stainless steel surface

Contact Now

Stainless Steel Coils are one of the most sought after types of raw material in the construction and manufacturing industries. Thanks to their distinct mechanical and physical properties, stainless steel coils have been widely used in the production of kitchen appliances to industrial equipment. They are strong, resist corrosion, are light in weight and require low maintenance. Stainless steel producers take advantage of the properties of stainless steel to improve quality through various surface treatments. We provide different types of stainless steel surface

Contact Now

301 Stainless Steel is a chromium nickel austenitic stainless steel capable of high strengths and ductility through cold working methods. It is not hardenable by heat treatment. Type 301 is non-magnetic in the annealed condition and becomes more magnetic and achieves optimal resistance to corrosion with cold working. 301 stainless steel is a modification of stainless steel grade 304 that contains lower chromium and nickel to increase the range for work hardening. Type 301 steel also exhibits corrosion resistance similar to grade 302 and grade 304.

Contact Now

Stainless Steel U Channel is a long steel strip with a grooved section. Same as I-beam, Stainless Steel U Channel can also be divided into ordinary channel steel and light channel steel. The model and specification are also expressed by waist height (h) × Leg width (b) × Waist thickness (d) expressed in mm, such as 120 × fifty-three × 5 Channel steel, that is, round steel with waist height of 120mm, shall be distinguished by adding a, b, c, etc. to the right of the model.Feathurs1.

Contact Now

Stainless Steel 301 is a commonly available austenitic stainless steel with good corrosion resistance and elevated carbon to allow for cold working to a variety of tempers. Grade 301 stainless steel is highly ductile, for formed products. It also hardens rapidly during mechanical working and has good weldability.Feathurs1. Stainless steel has different grades, correspond to different hardness, thermoplastic, plasticity and weldability. If you don't understand, you can tell us your requirements. 2.

Contact Now

Stainless Steel Coils are one of the most sought after types of raw material in the construction and manufacturing industries. Thanks to their distinct mechanical and physical properties, stainless steel coils have been widely used in the production of kitchen appliances to industrial equipment. They are strong, resist corrosion, are light in weight and require low maintenance. Stainless steel producers take advantage of the properties of stainless steel to improve quality through various surface treatments. We provide different types of stainless steel surface

Contact Now

Stainless Steel Coils are one of the most sought after types of raw material in the construction and manufacturing industries. Thanks to their distinct mechanical and physical properties, stainless steel coils have been widely used in the production of kitchen appliances to industrial equipment. They are strong, resist corrosion, are light in weight and require low maintenance. Stainless steel producers take advantage of the properties of stainless steel to improve quality through various surface treatments. We provide different types of stainless steel surface

Contact Now

316 is actually a stainless steel material, which contains a certain amount of Mo element. The performance of this steel has exceeded that of 301 steel and 304 stainless steel. It has a very wide range of applications. Even in high-temperature environment, it will not be eroded and corroded by high temperature. It can also be used in the marine environment, and will not be polluted by some outer air, resulting in corrosion.Feathurs1. Stainless steel has different grades, correspond to different hardness, thermoplastic, plasticity and weldability.

Contact Now